Whenever an arc-flash study is done or revised and new arc flash warning labels must be considered, it is a good idea to define exactly what information belongs on each label before starting to print anything. It is also a good idea to define how and where these labels will be applied before anyone peels the back off of the first adhesive label and sticks it onto anything. It is a very good idea to put those definitions into writing so that everyone who assists or who comes along later, has something to help them understand the original intent. This is particularly important as a means of trying to promote consistency and to avoid creating unnecessary confusion when an arc flash analysis study is spread out over extended period of time. A guideline document such as the one published here serves that purpose. The guideline describes how electrical equipment should be labeled, namely how many labels should be applied and in which locations, after appropriate data collection, modeling, short-circuit analysis and arc-flash study activities have been completed. The intent here is not to limit the number of labels applied but rather to insure that at least the required minimum number of labels are in place. This document also addressed the question of how to label devices that were subject to protection under a selectable maintenance settings scheme. This application involved two labels as shown in Figure 6.

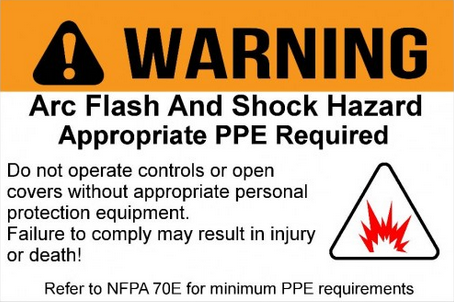

The arc-flash labels discussed herein are required by the NEC in article 110.16 and by NFPA 70E in Section 130.7 (E)(1). There are two basic types of arc flash labels that should be used. They are a generic label - one that does not include specific calculated data but which identifies the existence of the hazard and refers the reader to the site 70E policy, and a specific label - one that includes calculated data for arc-flash incident energy or hazard/risk category and identifies specific required PPE. Figure 1 shows one of each type of label, with the generic type being the upper label. This guideline identifies what type of equipment we should be labeling and how to label that equipment. If a piece of equipment is identified by company guidelines as within the scope of equipment for which we should be calculating arc-flash exposure, then the label should be a specific label. Otherwise, the label will be a generic label and will refer to the overall site 70E policy. Wherever specific labels are applied, they shall describe all of the requisite PPE.

Figure 1A. An example of generic arc flash warning label.

Figure 1A. An example of generic arc flash warning label.

Figure 1B. An example of specific arc flash warning label.

Many facilities have been through short-circuit and arc-flash studies conducted under previous versions of the NFPA 70E regulation. In such cases, it is possible that the labels already in place in the field reflect older hazard levels and types of PPE for some of the labeled equipment and are no longer correct for the current version of NFPA 70E. It is permissible to hand-modify the existing labels if the changes are somewhat minor, but it is often confusing to do that. The preferred approach is to relabel the equipment. However, since the current version of the regulation requires review and update on a five-year cycle, it is recommended that the labels simply be corrected during the course of the next overall update.

The generic label is a Brady product, while the specific label is a product printed as output from Arc Flash Analytic software program. Both of these labels use the ANSI Z535.4 "warning" format and an orange banner. The "danger" format with a red banner, described in the same ANSI standard, is equally acceptable.

Read more at http://arcadvisor.com/faq/arc-flash-labeling-guidelines